You are here

Unveiling the Secrets of Notre Dame’s Materials

Stone by stone, beam after beam, the removal of the first pieces of debris from Notre-Dame de Paris began shortly after the blaze that devastated the edifice on 15 April this year. This huge mass of timber, iron and stone materials records the history of the cathedral, and is now undergoing expert assessment by French scientists. Despite the tragedy, the fire has opened up an exceptional opportunity to access these materials, which were often located in the highest parts of the monument. Some of them have never been analysed, starting with the wooden roof structure known as the “forest”, made up of thousands of oak beams assembled eight hundred years ago.

A post-mortem analysis of the roof structure

“There are probably around 2,000 pieces of timber to be studied, some of which are intact or only partially charred,” explains Bernard Thibaut, CNRS senior researcher emeritus at the Mechanics and Civil Engineering Laboratory (LMGC) in Montpellier (southern France).1 For the moment, very few people have access to the debris in the cathedral, since it is too unsafe. “Wood always provides us with invaluable records,” the scientist explains. Analysing the beams of Notre-Dame will help the researchers to further their knowledge of the roof structure, such as the origin of the oaks, their age, how they were grown, and so on. “DendrochronologicalFermerDendrochronology is a method of dating wood using tree rings. analysis of the tree rings should also tell us when the trees were felled,” he adds.

The characteristics of the framing are not totally unknown though. Frédéric Épaud, a researcher at the CITERES laboratory2 in Tours (central western France), examined it after the fire and compiled a number of studies that debunk some popular misconceptions. “This roof structure held up for eight hundred years, whereas no one would guarantee a lifespan of more than a century or two for a modern one. That’s quite exceptional,” Bernard Thibaut points out. “In France, there are fewer than ten roof frames with this load distribution system, providing evidence of a distinctive approach specific to Gothic architecture in the Ile-de-France region," Frédéric Épaud adds. Research will therefore focus on understanding how the wood has been impacted by time, and the effect of centuries of physical stresses on the beams.

The wood’s physical and chemical properties, variations in density and resistance will also be investigated. “For instance, I am curious to know why Notre-Dame's structure has remained almost free of insect attack, even though it has never been treated," Bernard Thibaut muses. Remarkably, the sapwood, normally a target for attack by larvae, is completely untouched even after eight hundred years. “This might be due to the presence of tannins, which lend their distinctive odour to oaks and chestnuts and may act as a repellent,” the scientist surmises.

For now, this research work is still in its infancy. Funding has been slow to arrive, much to the regret of the two wood specialists, who are hoping that reconstruction will take inspiration from a scientific understanding of the roof structure. Both of them believe that the obvious thing to do is reconstruct the roof frame exactly as it was. “When you see a structure that has lasted nearly a thousand years, it doesn’t seem unreasonable to draw inspiration from it,” Bernard Thibaut says. The two experts hope that the same varieties of highly-resistant oaks will be used for the restoration. Around 30% of French forests are made up of oak trees, numbering nearly 200 million. A species that is “underrated” according to Bernard Thibaut, who points out that “there are now more oaks in France than there were in the Middle Ages”.

The researchers also suggest resorting to the techniques employed to squareFermerCutting technique designed to give a tree trunk a square or rectangular section. wood at the time, when the axe was preferred to the saw. “As in the twelfth century, using an axe is an efficient technique that takes little time, and, most importantly, is environmentally friendly. Everything can be done on the spot, and very little wood is wasted in the production of a beam. Moreover, this kind of beam is more stable than one made by sawing wood,” insists Frédéric Epaud, “a fierce supporter of identical restoration”, who laments the involvement of the concrete and sawmill industries in the debate.

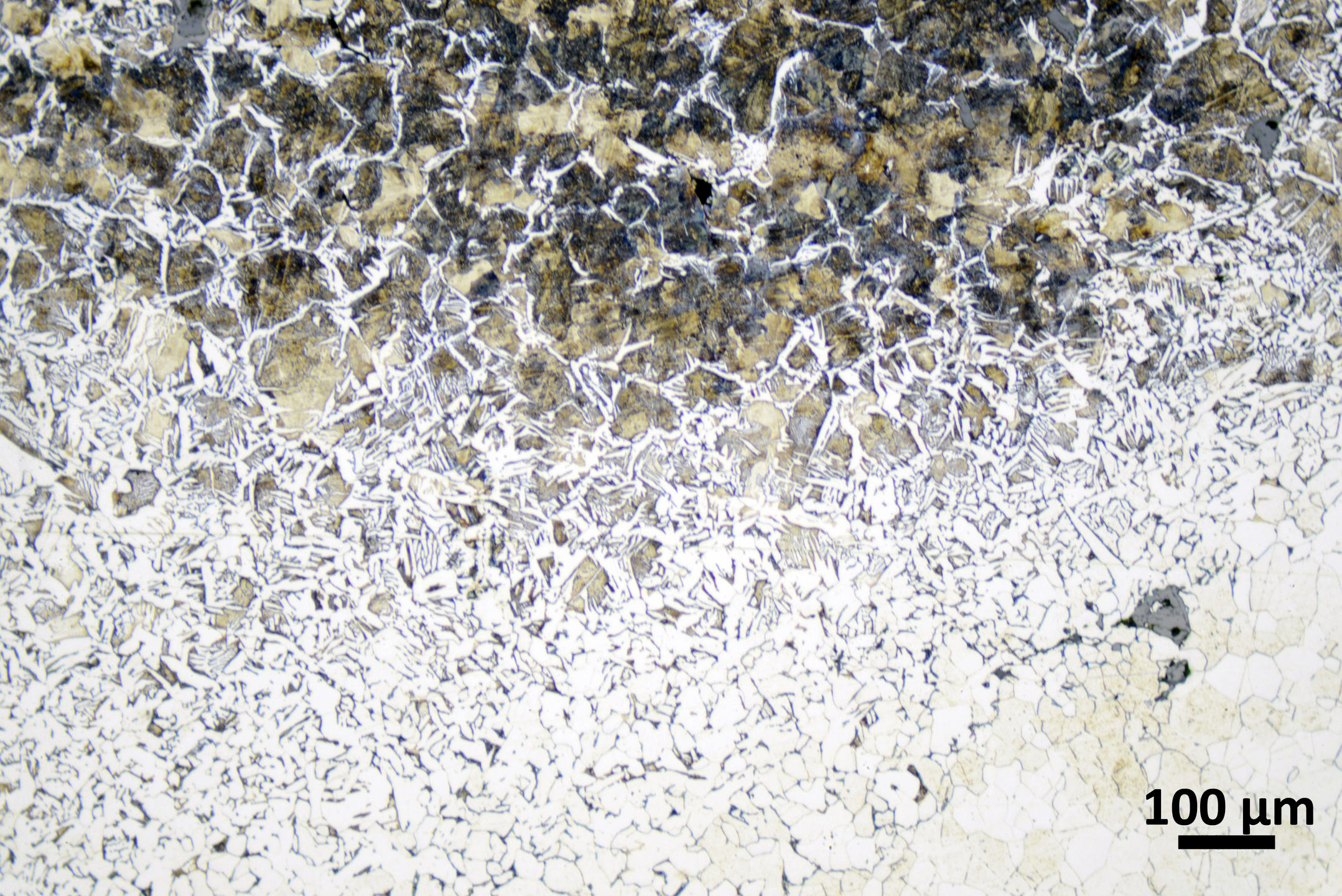

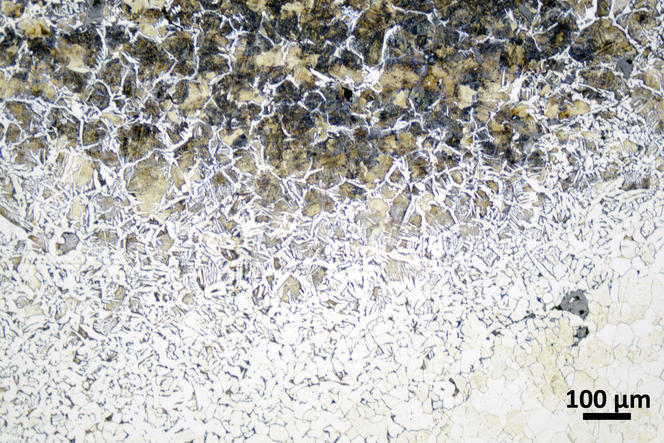

The cathedral’s calcined limestone

The question of how to restore the materials of Notre-Dame also applies to the stonework. Consisting of Lutetian limestone, it was damaged by both the fire and the water used to put it out. “Heat cooks the limestone, which decarbonates (in other words, its CO2 evaporates), loses its cohesion and turns into lime,” explains Philippe Bromblet, a research engineer at the Models and Simulations for Architecture and Heritage laboratory (MAP)3 at the Interdisciplinary Centre for Heritage Conservation and Restoration (CICRP). “Heated and then drenched with water, Notre-Dame’s stone has lost its strength, while its mechanical properties have been altered.”

Within the same quarry, the characteristics of Lutetian limestoneFermerSedimentary layer, typical of the Paris Basin, dating back 40 to 45 million years. vary considerably depending on the bedFermerIn geology, a sedimentary layer that is usually extensive but not very thick. it is extracted from. “One type of limestone called lias is very strong, and is used preferentially in the parts of the building designed to carry heavy loads,” Philippe Bromblet explains. “The physical and chemical properties of the stone are not the same throughout the cathedral.”

The stone used to build Notre-Dame was extracted from underground quarries dug beneath Paris’s fifth and twelfth arrondissements. It was also employed for the construction of the Chateau of Versailles and that of Vaux-le-Vicomte (both in the Paris region), as well as for the Reims cathedral (northeastern France). “Of course, this stone is no longer quarried there, so we won’t be able to extract it to rebuild Notre-Dame,” the researcher explains. In France very few quarries are still worked, and even fewer for this type of limestone. “Most of them closed in the twentieth century, with the arrival of concrete,” he adds. Although a decree authorises the reopening of small quarries for the restoration of monuments, “this is very complicated from a regulatory and ecological viewpoint, and is actually impossible within the Paris conurbation. However, there are outcrops in the Ile-de-France region where it might be possible to open a pit for the restoration of the cathedral.”

A substitute stone could be used. However, “the ideal solution would be to keep the original one if its state allows”, the researcher says. The first stage would be to take the stone out and dry it, “so that it can recover its original quality, and probably then sort out the pieces that can be reused by assessing the impact the fire and water have had on their mechanical properties”.

Another approach being considered is to find ways of consolidating the stone by using treatments based on silica, nanoparticles or biomineralisation. The latter “consists in feeding bacteria on the stone’s surface, which then produce calcite and repair it”, Philippe Bromblet explains. For now, this technique can only help to restore the surface, but research is being carried out on new strains of bacteria that could act at greater depth. “This is a totally ‘natural’ route that we are going to test out on a twelfth century church in the Montpellier region ,” the scientist says. If it turns out to be effective, it could be used to consolidate certain parts of Notre-Dame, such as those most exposed to rainfall.

Dating Notre-Dame’s iron

One of the advantages of the Notre-Dame working groups is that they bring together a large number of researchers around a single material. And in recent weeks, a research group on the metal in Notre-Dame has been set up to study the monument’s iron. "We will try to find out whether iron wall ties were embedded in the twelfth and thirteenth century masonry to consolidate the structure, as is the case in the nave of the Basilica of Saint-Denis, which dates from the same period," explains Maxime L'Héritier, a lecturer in mediaeval history at the Université Paris-8 and a member of the ARSCAN laboratory.4

In the second stage of the research, carbon-14 will be used to date the iron. “Cathedrals are usually built with a mixture of iron and steel, itself an alloy of iron and carbon. To date the iron, we therefore date the carbon in the steel, which comes from the charcoal used to reduce the ore. This gives us the age of the tree the charcoal came from, with the same accuracy as standard carbon-14 dating,” the scientist explains. The technique has already been used in Bourges cathedral (central France) and the Sainte-Chapelle in Paris.5

Determining the age of the iron in the cathedral will thus make it possible to reconstruct the history of the masonry and roof structure, “since will be able to find out whether the iron originates in the twelfth, thirteenth, fifteenth to sixteenth centuries or later, and in this way trace the various stages of construction and reinforcement,” the researcher adds. This would be a real godsend, since there are very few records of such potential consolidation work.

The quality of the iron, as well as its geographical origin, will also be investigated by means of metallographic tests. “The impurities found in the metal can be used to trace the geographical source of the ores at that time. Chemical reference databases have been compiled in recent years by researchers at the IRAMAT6 and the LAPA.7 So we’re not completely starting from scratch,” the historian points out.

Seeking the chemical signature of Notre-Dame’s lead

Present not only in the cathedral’s roofing and in its spire, both dating from the nineteenth century, but also in some of the internal sealing (to hold the stained-glass panels in place for example), most of the lead has melted. And analysing it scientifically is no easy task. “Very few archaeological and analytical studies have been carried out on lead. The problem is that it melts and re-melts, which means that it is theoretically impossible to date, unlike iron, which always exhibits tiny internal weld marks after recycling,” Maxime L’Héritier explains.

The research group therefore wishes to set up a chemical reference database based on the most stable isotopes of lead. “Hopefully, this will take us back to the ores used. But above all, knowing the isotopic signature of the metal will enable us to understand how lead from various sources was mixed and recycled up until the nineteenth century. Establishing such a database will also help us to provide answers to questions about lead pollution,” the scientist hopes. For now, the concentrations of lead dust and lead oxide in the air and in water are being measured, in particular to guarantee the safety of the site.

“Once we know the geochemical signature of Notre-Dame's lead, we can compare it with that found in the local population and in the environment, to be sure that it comes from the cathedral and not from other sources, such as pipes," Maxime L’Héritier says. In this way, he hopes to be able to contribute to the ongoing public health debate about lead pollution from the Notre-Dame blaze, where controversy still rages despite the decontamination work carried out this summer in the surrounding buildings and on the site itself. In his opinion, restoring the lead roofing to its original state makes sense, “provided the environmental impact is assessed”.

- 1. (CNRS / Université de Montpellier).

- 2. Cités, territoires, environnement et sociétés (CNRS / Université de Tours).

- 3. CNRS / Ministère de la Culture.

- 4. Archéologies et sciences de l’Antiquité (CNRS / Université Panthéon-Sorbonne / Université Paris-Nanterre / Ministère de la Culture).

- 5. Collaboration between the Institut de Recherche sur les Archéomatériaux, Laboratoire Archéomatériaux et Prévision de l’Altération, Université Paris-8 and Artemis-LMC 14.

- 6. Institut de recherche sur les archéomatériaux (CNRS / Université de technologie de Belfort-Montbéliard /Université d’Orléans / Université Bordeaux-Montaigne).

- 7. Laboratoire archéomatériaux et prévision de l’altération - Nanosciences et Innovation pour les Matériaux la Biomédecine et l’Energie (CNRS/CEA).

Explore more

Author

Léa Galanopoulo has a biology degree and is currently studying scientific journalism at Paris-Diderot university.