You are here

The Dawn of Flexible Electronics?

You must have seen them while doing your Christmas shopping: those curved televisions only a few millimeters thick are a dream for many! Behind these ultra-flat screens, a specific technology, that of OLED1—or so-called organic LED— is the vehicle for a new kind of electronics. If certain agencies already estimate that the organic electronics market exceeds 20 billion dollars, experts unanimously point out that new applications are still to come. Whether it be flexible, rollable, recyclable, or printed electronic devices... Welcome to the organic world of soft smartphones and intelligent environment.

When polymers replace silicon

Today, electronics is dominated by mineral components, especially silicon, for its robustness and high-performance. Chips in microelectronics, photovoltaic panels, screens...everything (or almost) contains silicon. Its ever-growing market amounts to a few hundred billion dollars. Yet an alternative to the use of minerals emerged in 2000, as the Nobel Prize in Chemistry was awarded to Alan J. Heeger, Alan G. MacDiarmid, and Hideki Shirakawa for their discovery of polymer conductors. Polymers are the very long molecules that make up plastic materials, natural fibers (cellulose, keratin...), rubbers, glues, paints, resins...Unlike silicon, which is extracted from the mineral world, polymers come from the living world, or are synthesized in the laboratory. The fact that plastics can be conductors or semi-conductors is therefore a revolution. "Since these materials can be manipulated in the form of ink, it was quickly envisaged to print circuits at low cost, using inkjet printers on flexible media with large surfaces, in the same way as newspapers. Such procedure was previously made impossible by the rigidity of silicon," says Lionel Hirsch, a researcher at the IMS,2 and director of the CNRS Organic Electronics research network. From then on, organic technologies made a leap forward.

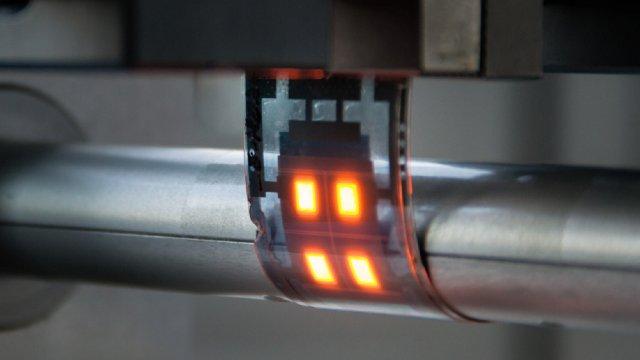

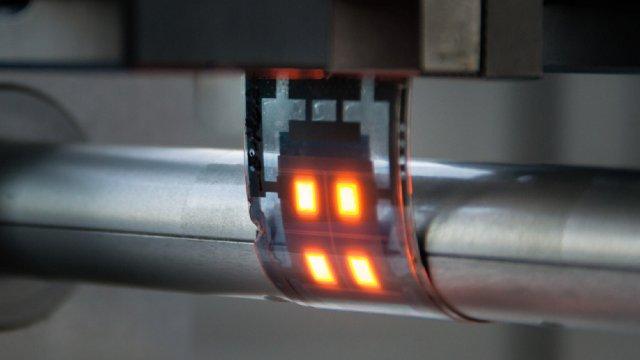

The figurehead of this new trend is certainly OLED, for organic light-emitting diode, which is beginning to take over our screens. In light of its characteristics, it could very well dominate the market one day, despite its cost, which remains high. OLED is brighter, displays greater contrast, and allows screens to be ultra-flat (only a few millimeters), curved, and even flexible...In an LCD or LED screen, the numerous layers assembled in front of a backlit system do not allow for ultra-flat screens. However OLED emits both light and color, thus greatly reducing the thickness of the screen. "The market is exploding, but the product is still expensive, due to fairly low production yields, since achieving zero defects in a screen measuring one meter in diagonal remains complicated. This also explains why OLEDs are more frequently found in smartphones," explains Ian Cayrefourcq, director of Emerging Technologies at Arkema, a partner company of the CNRS. "But it is only a matter of time: given the investment of certain companies, production costs for OLED screens will fall in years to come."

Printed electronics

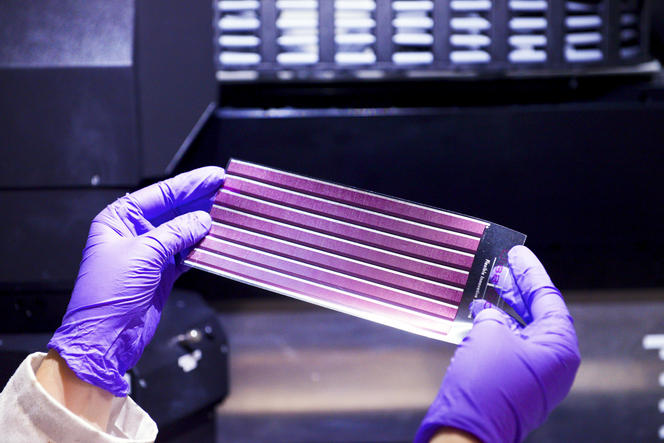

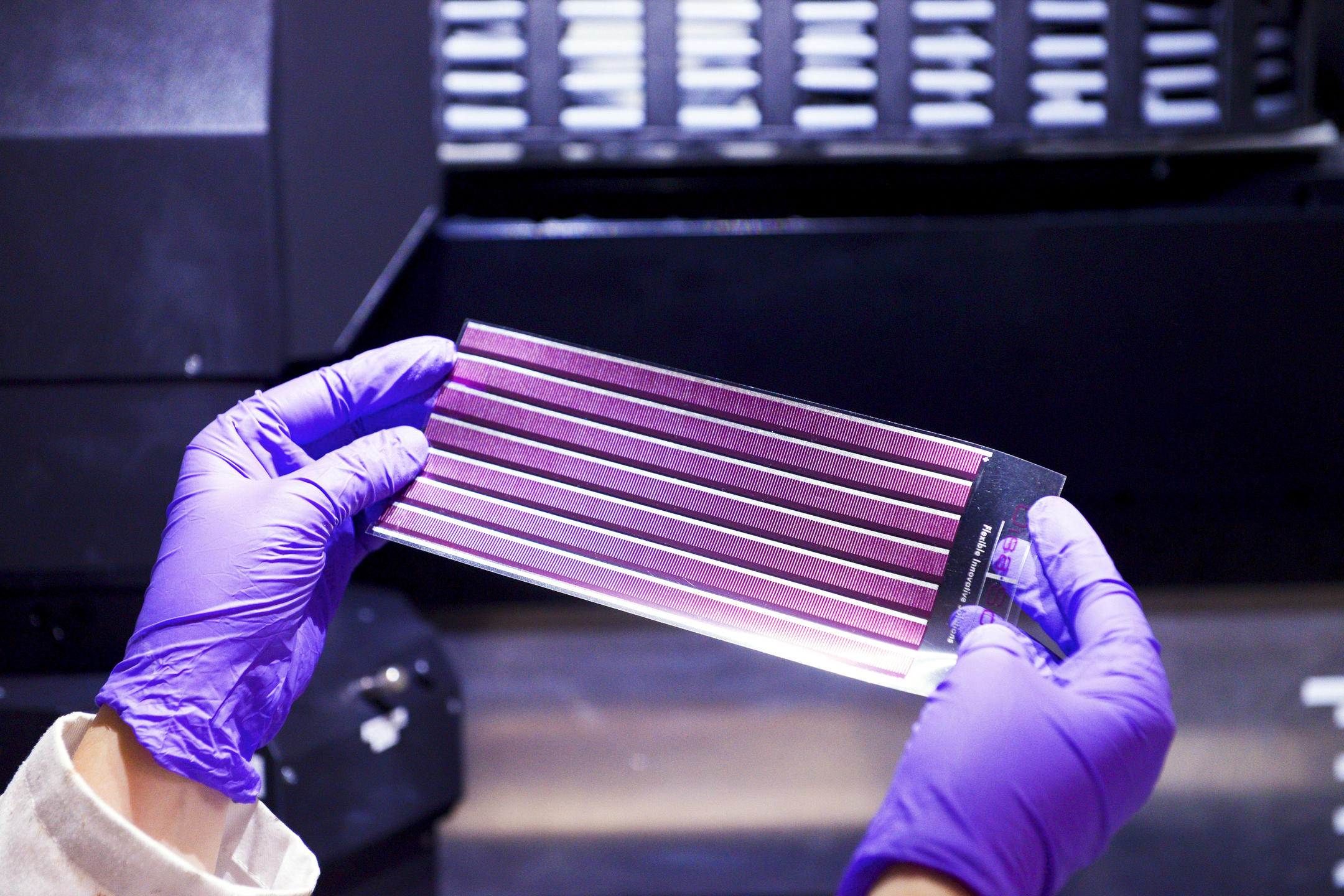

Another field of application for organic electronics is that of sensors and other flexible printed devices. "At Arkema, we developed inks for memory, pressure and temperature sensors, as well as touch responsive inks," continues Cayrefourcq. "We are entering the age of the intelligent environment, which requires sensors everywhere to manage energy consumption, detect the presence of people, or handle the cold chain for food. But no one will want to pay over the odds for one." And such flexible sensors can be produced for the price of an inkjet printout. Photovoltaics are also a focus. The French group Armor, specialized in inks and printing, will start selling its first organic solar cells this year, as part of its new "energy" project called Beautiful Light. Another trend favorable to printed electronics is Energy Harvesting. The concept involves gathering from everyday actions the small amounts of energy needed to power small devices. In the future, sneakers will contain sensors to calculate the calories burned, while at the same time harvesting the energy from the run to power a portable music player; photovoltaic paint on advertising boards will supply their lighting with full autonomy.

The latest object of fantasy for technophiles the world over is flexible devices, such as the soft smartphones presented at conventions or crowdfunding projects. However, before reaching these targets, researchers still have a lot on their plate.

The hurdle of encapsulation

The technology is not entirely mature. "Globally, the main problem of organic materials for electronics comes from their lack of stability, and therefore their lifespan. Take the example of a solar cell: exposure to the sun and heat will modify the size and nanostructure of the organic photovoltaic materials, and thus degrade them. They must therefore be encapsulated to protect the devices, and this is true for all applications," explains Hirsch, as he emphasizes the progress being made. "For instance, this year we achieved a breakthrough by developing an additive that makes the active material of organic solar cells insensitive to temperature.3"

Encapsulation, which is necessary for all applications, is a brake on this much-awaited flexibility. "Today OLEDs in screens are embedded between plates of glass," explains Georges Hadziioannou, formerly of IBM and now researcher at the (LCPO).4 “Glass is a good encapsulant, but is by no means flexible. Our research therefore aims to both make active materials more stable and improve flexible encapsulation. We have recently developed a new additive as well. It increases the yield of solar cells and makes their production compatible with a flexible medium."5 As for screens, the material used in touch displays, ITO (indium tin oxide)—which serves as a transparent electrode and lacks flexibility—will have to be replaced. The race is on at the global scale! Approached by German partners,6 Hadziioannou's team very recently developed, in collaboration with Arkema, a conductive ink that forms a transparent conductive film entirely made of organic polymers. Its performance in terms of flexibility and printability is very promising compared with other organic competitors of ITO developed across the world.

In this international competition over printed electronics, France has set up meeting facilities for public and private researchers. Led by Hadziioannou, in conjunction with Arkema, ElorPrintTec7 is a new Bordeaux-based platform whose 1,000 m² dedicated to flexible and printed technologies for organic electronics, can accommodate 130 researchers, both from academia and industry. All applications are concerned: OLED for lighting and display, photovoltaics, sensors, batteries, etc. "Investing in printed technologies does not cost as much as favoring classical branches of electronics. SMEs can start up with limited risk. Access to this platform will boost these investments," adds Hadziioannou. French SMEs are beginning to mushroom: Isorg in Grenoble for sensors, DisaSolar in Limoges for photovoltaics, Astron Fiamm in Marseille for OLED lighting...When will these niche markets become mainstream? It could happen in the next five to ten years, although it is difficult to say at this stage. Yet Cayrefourcq and others are confident, for "investments by industry in the high-tech sector, notably from Korea, will be beneficial to organic electronics as a whole." With a bit more patience, smartphones could become as soft as rubber.

- 1. Organic light-emitting diode.

- 2. Laboratoire de l'intégration du matériau au système (CNRS /Université de Bordeaux / Bordeaux Aquitaine INP).

- 3. L. Derue et al.,"Thermal Stabilisation of Polymer-Fullerene Bulk Heterojunction Morphology for Efficient Photovoltaic Solar Cells," Advanced Materials, 2014. 26(33): 5831–38.

- 4. Laboratoire de chimie des polymères organiques (CNRS./Université de Bordeaux / Bordeaux Aquitaine INP).

- 5. C. Renaud et al.,"Block Copolymer as a Nanostructuring Agent for High-Efficiency and Annealing-Free Bulk Heterojunction Organic Solar Cells," Advanced Materials, 2012. 24(16): 2196–01.

- 6. Fraunhofer Center for Organics, Materials and Electronic Devices Dresden.

- 7. CNRS / Université de Bordeaux, / Arkema / Bordeaux INP, in collaboration with the CEA / Investissements d'Avenir.

Explore more

Author

Jonathan Rangapanaiken is a Communications officer for the Institute of Chemistry of the CNRS.