You are here

Sweet Eco-friendly Materials

Sucrose, glucose, fructose, lactose...The sugar family offers a spectacular range of molecules that do not just make life sweeter. From medicine to nanotechnologies and industry, sugars are now also being used to develop eco-friendly biosourced materialsFermerDerived from animal or plant biomass. materials. This is the case for polysaccharides, which are made up of building blocks of simple sugars (monosaccharidesFermerSimple carbohydrates, referred to as "fast sugars" in the food world. The most familiar on our plates are glucose, fructose, etc.). These polymersFermerVery large molecules consisting of the repetition of numerous sub-units. can be obtained using different by-products from industry (food-processing, paper, etc.), and provide excellent alternatives to the chemistry of petroleum derivatives.

Chitosan, an extract from crab and shrimp shells that has been known since 1859, is among the most surprising. Used as a flocculant to process wastewater as well as in cosmetics and food, "its use has steadily increased over the last forty years," explains Laurent David, professor at the Université Claude-Bernard in Lyon and member of the IMP laboratory.1 "Technological progress has helped improve the purity of products from biomass, making it possible to use these materials for biomedical applications."

Regenerative Bandages

Laurent David, for instance, is working on hydrogels. These products, made up of up to 99% water, only contain small amounts of polysaccharides such as chitosan. "Living tissues are themselves hydrogels," he points out. "This structural similarity reduces inflammatory response and promotes tissue reconstruction."

Injected quickly after a lesion of the spinal cord, fragmented chitosan hydrogels can stimulate nervous tissue regeneration in vivo, although natural formation of nervous scar tissue no longer allows information to travel through the lesion. Moreover, these materials, which are highly permeable to oxygen, nutriments, and hormones, offer hitherto unseen in vitro conditions for fostering ex vivo spermatogenesis, thereby opening up new prospects for preserving fertility among young boys or infertile adult men.

Chitosan also blends well with other polysaccharides, such as alginates extracted from seaweed. Working in collaboration with the Paris-based Brothier laboratories, Laurent David has designed bandage strings that combine these two materials to regenerate tissue.

His team also produces chitosan strings, which are good candidates for the development of mesh linings to treat hernias or aneurysm in blood vessels. This is a promising material for these applications because of its low inflammatory response and resorption properties, which can be controlled over time.

Other applications aimed at purifying water, fixing colorants, or fighting fungus and bacteria are in the pipeline...

High-Resolution Resins

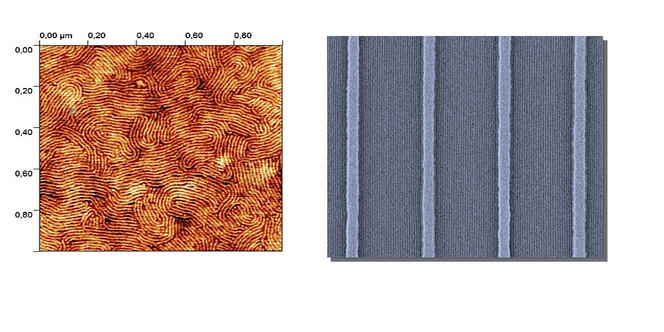

Polysaccharides also have unexpected uses in cutting-edge microelectronics. Redouane Borsali, a senior researcher at the CERMAV2 and director of the PolyNat Carnot Institute, is leading the efforts of eight laboratories in Grenoble (southeastern France) towards high value-added biosourced materials. His research on controlling the architecture and properties of biosourced copolymers has earned him numerous prizes, the most recent of which was the France-Taiwan Scientific Foundation Prize handed out by the French Académie des Sciences for transistor memory devices. "It all boils down to building blocks. It can be a combination of one, two, or three sugars," the scientist explains. "We are moving towards the design of biosourced copolymers with controlled architectures, in an effort to obtain new building blocks. These will lead, by way of self-assembly, to new ultra-nanostructured biomaterials with a resolution of a few nanometers."

These blocks then self-assemble, while researchers control various parameters, depending on the properties they want to obtain. In connection with the GreeNanoFilms European project, Redouane Borsali uses copolymers based on glucose, sucrose and cyclodextrin to create the ultrathin films needed for nanometric lithography. In addition to being biosourced, these resins have a resolution that is four times greater than that of petroleum-derived materials.

"The Japanese microelectronic industry, including Toshiba, Hitachi, and Tokyo Electron, is showing a keen interest in our patents," Redouane Borsali enthuses. "With our improved resolution, we can store six times more data on the same surface than would be possible with a petroleum-derived system. This will eventually become twenty to thirty times more." These materials also find applications in organic LEDs, photovoltaic cells, and biosensors on flexible substrates.

Reinforced Tires

Another sugar-based product familiar to the paper industry is cellulose. Laurent Heux, deputy director of the CERMAV, unravels its natural structure to isolate the smallest possible building blocks, in a bid to develop new materials.

"We deconstruct plant matter until we reach the nanometric scale," he explains. "Depending on the method, we either obtain cellulose nanocrystals that look like grains of rice, or cellulose micro/nanofibrils, which are reminiscent of spaghetti." These objects are only a few nanometers in diameter, and their length ranges from a few hundred nanometers to a few micrometers.

Controlling their structure has enabled the CERMAV team, working in collaboration with the French multinational Michelin, to reinforce the elastomers used in tires. The scientists also designed iridescent liquid crystals by imitating cellulose organisation in a type of African fruit. The study of cellulose echoes Grenoble's past as a bastion of the paper industry.

In addition to the CERMAV, the city is home to the Centre Technique du Papier research centre and to Pagora, a specialised engineering school, which work hand in hand within the Polynat Carnot Institute. According to Laurent Heux, the cellulose industry is exploring new prospects with greater added value than paper.

"There are various reasons for the popularity of biosourced materials," the researcher suggests. "While higher production costs can sometimes be a deterrent, industrial players are keeping a close eye on these products to address growing constraints on petroleum derivatives and evolving legislation reflecting societal demands for more environmentally-friendly materials." In any event, research on sugars continues to provide new results, with biosourced products boasting ever-improved properties and increasing added value.

Explore more

Author

A graduate from the School of Journalism in Lille, Martin Koppe has worked for a number of publications including Dossiers d’archéologie, Science et Vie Junior and La Recherche, as well the website Maxisciences.com. He also holds degrees in art history, archaeometry, and epistemology.