You are here

Personalised breast reconstruction

Breast cancer is the most common cancer among women in France. More than two million are diagnosed each year throughout the world, and 40% of them undergo a mastectomy – or total removal of a breast – in order to facilitate recovery. But although several techniques are currently available, only a minority of patients choose to undergo reconstruction following their surgery, because they fear medical complications or unsatisfactory aesthetic results. Set up in January 2020 in Lyon (southeastern France), Healshape aims to provide a response to these fears in the form of innovative breast reconstruction based on bioprinting and advanced tissue engineering technologies.

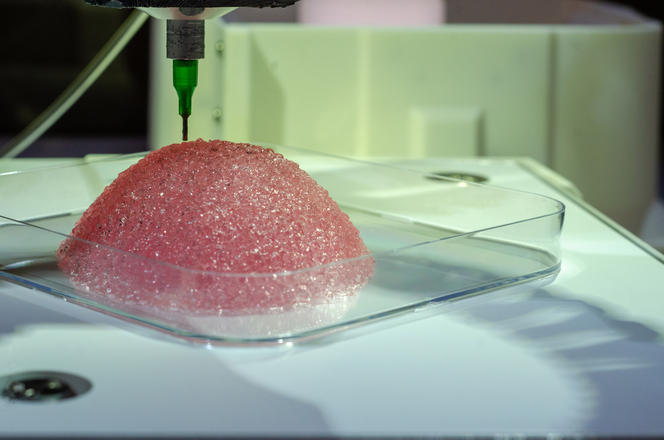

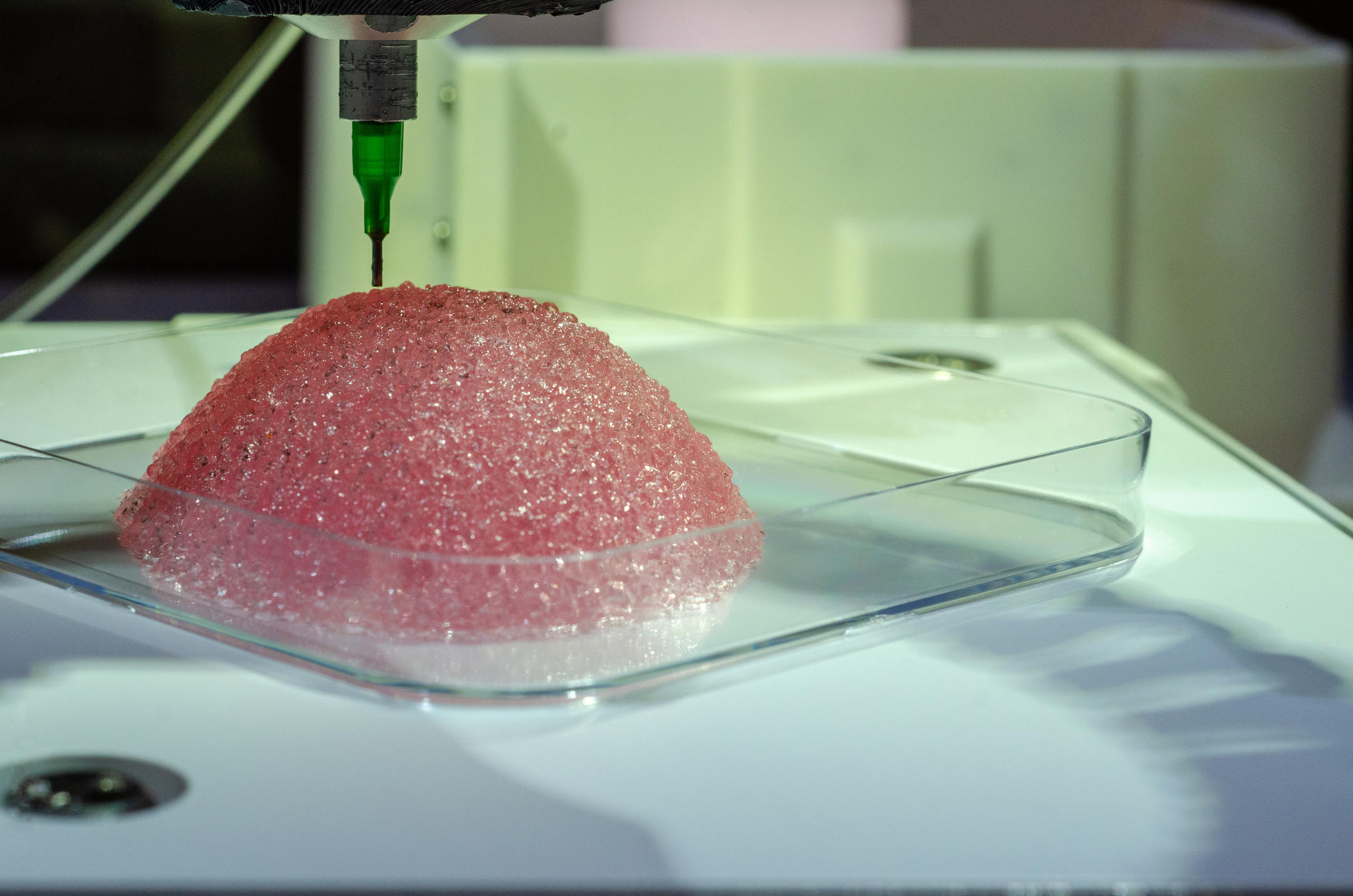

A resorbable bioprosthesis

Healshape has thus developed a bioprosthesis using natural, resorbable hydrogel. This 3D bioprinted implant can adapt to all body shapes. Once the prosthesis is in place, the patient’s own cells from a fat transfer will colonise the personalised shape and recreate breast tissue, at the same time as the bioprosthesis is gradually resorbed. “A woman will recover her own breast within six to nine months, with no trace of the bioprosthesis,” says Sophie Brac de la Perrière, CEO of Healshape, who hopes that “this will help women accept their image and be happy with their bodies again.”

This innovation in regenerative medicine is based on the bioprinting studies that were achieved through collaboration between the research group led by Christophe Marquette, a CNRS senior researcher at the ICBMS1 and manager of the 3d.FAB platform, and the company LabSkin Creations,2 which specialises in advanced tissue engineering of the skin and adipose tissues.

Patented biological ink

The various partners joined forces to create a biological ink for which a patent was filed jointly with the CNRS. This ink enables reconstruction by means of bioprinting: “Initially, the technology was developed to print skin substitutes. For the Healshape project, it was necessary to adapt the process to printing volumes, and ensure subsequent consolidation of the biological ink to make it compatible with implantation in the body,” explains Marquette.

Healshape now enjoys an exclusive licence on this patent and know-how, along with its six co-founders, who include Marquette, the founders of LabSkin Creations, as well as a pharmacist and surgeon. Incubated by the deep tech innovation accelerator company Pulsalys, and by Les Premières AURA (which supports women and mixed teams in the creation and development of innovative start-ups), Healshape was one of the winners of the i-Lab national innovation awards in 2020. The start-up is currently at the preclinical stage and hopes to initiate clinical trials within the next two years.