You are here

Transcript

Close

Millions of years of evolution have fashioned birds into Nature’s most finely-tuned flying machines.

Today, humans wish to copy their extreme efficiency in order to build the airplanes of tomorrow.

Engineers are working on two distinct features :

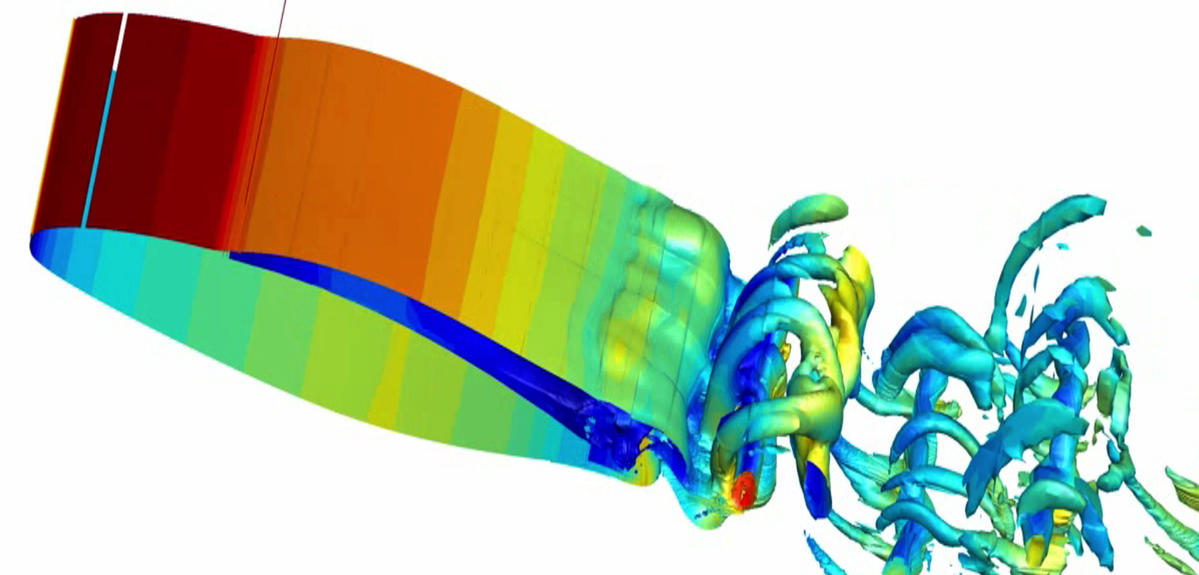

the ability for a bird’s wing to change shape in real time and the noise-reducing properties of the small feathers that break the turbulence at their tips…

In the French city of Toulouse, two research centers are collaborating with Airbus to build aircraft wings using innovative materials that can adapt their shape in the presence of an electrical current. A property called electroactive morphing.

ITV Marianna Braza

Physicist

This morphing will reshape the wing of a future aircraft in order to increase its performance in flight.

Two models of electroactive wings were created

at the plasma and energy conversion laboratory.

The main element is a shape-memory alloy that can be controlled electrically.

ITV Marianna Braza

An electrical current brings these materials to life !

ITV Jean-François Rouchon

University professor – Electrodynamics

There are two corresponding features we wish to have on our wings. The shape-memory alloy may help reduce low-frequency turbulence, whereas higher-frequency turbulence may be controlled or limited with a type of piezoelectric materials.

These materials, placed at the tip of the wing, will reduce the turbulence responsible for noise during takeoff and landing.

ITV Christophe Cros

Airbus engineer

The technique that we are going to study at the MFT l’institut Laplace research center, is inspired by the wings of large birds. The motion that we wish to create on the trailing edge, the extremity of the wing, is going to interact with the airflow on the wings and break the turbulence that usually occurs.

Ambiance :

Look out for the cable. We’re going to try and come in from above.

How about I come down and you come up ?

It’s the first time I see it assembled.

And what are you going to do for this joint ?

It’s just going to be heavy-duty tape.

For the scientists, it’s an important day. They are about to test their wing model for the first time in the wind tunnel of the institute of fluid dynamics in Toulouse.

Just like birds, these materials will use the wind’s energy to fly. But they also have the ability to store some of that energy and release it later.

ITV Marianna Braza

The properties of these electroactive materials enable us to tap and store some of the vibratory energy that exists in all flight situations. This energy can then be used to power the morphing.

ITV Karl-Joseph Rizzo

Postdoctoral fellow

Let's compare the wing with what exists in Nature. Here we managed to create a wing with feathers that are able to move, we have a central muscle that modifies its shape and we also added some cognitive function. We get feedback so we know exactly how the muscle bends. So we are able to sense and act upon it to control the wing’s form.

We are happy because everything seems to function correctly and even better than expected. This is a world first, so we are more than satisfied ; quite moved, in fact...

ITV Christophe Cos

The advances we are aiming for are many-fold. They depend on which phase of the flight we are looking at. One possible benefit for instance is noise reduction during takeoff and landing. This is directly linked to the airplane’s aerodynamics.

At cruising speeds, we hope to reduce the drag. This is the force that counters the plane’s forward motion. By reducing this drag, we are going to boost the aircraft’s efficiency and cut its fuel consumption.

What will be the next step ? How do we go from a lab experiment to the wing of the future ?

We are now going to try to capitalize on our results – try and go from the small-scaled model that we have in the lab to a full scale that will enable us, I hope, to equip a one-to-two meter span wing.

In approximately a year, we are going to test an intermediate model in this wind tunnel. If the concept keeps its promises, the next step will be to lauch a pre-development industrial phase with Airbus and its wing experts. We eventually hope to be able to conduct an actual in-flight test.

Today, humans wish to copy their extreme efficiency in order to build the airplanes of tomorrow.

Engineers are working on two distinct features :

the ability for a bird’s wing to change shape in real time and the noise-reducing properties of the small feathers that break the turbulence at their tips…

In the French city of Toulouse, two research centers are collaborating with Airbus to build aircraft wings using innovative materials that can adapt their shape in the presence of an electrical current. A property called electroactive morphing.

ITV Marianna Braza

Physicist

This morphing will reshape the wing of a future aircraft in order to increase its performance in flight.

Two models of electroactive wings were created

at the plasma and energy conversion laboratory.

The main element is a shape-memory alloy that can be controlled electrically.

ITV Marianna Braza

An electrical current brings these materials to life !

ITV Jean-François Rouchon

University professor – Electrodynamics

There are two corresponding features we wish to have on our wings. The shape-memory alloy may help reduce low-frequency turbulence, whereas higher-frequency turbulence may be controlled or limited with a type of piezoelectric materials.

These materials, placed at the tip of the wing, will reduce the turbulence responsible for noise during takeoff and landing.

ITV Christophe Cros

Airbus engineer

The technique that we are going to study at the MFT l’institut Laplace research center, is inspired by the wings of large birds. The motion that we wish to create on the trailing edge, the extremity of the wing, is going to interact with the airflow on the wings and break the turbulence that usually occurs.

Ambiance :

Look out for the cable. We’re going to try and come in from above.

How about I come down and you come up ?

It’s the first time I see it assembled.

And what are you going to do for this joint ?

It’s just going to be heavy-duty tape.

For the scientists, it’s an important day. They are about to test their wing model for the first time in the wind tunnel of the institute of fluid dynamics in Toulouse.

Just like birds, these materials will use the wind’s energy to fly. But they also have the ability to store some of that energy and release it later.

ITV Marianna Braza

The properties of these electroactive materials enable us to tap and store some of the vibratory energy that exists in all flight situations. This energy can then be used to power the morphing.

ITV Karl-Joseph Rizzo

Postdoctoral fellow

Let's compare the wing with what exists in Nature. Here we managed to create a wing with feathers that are able to move, we have a central muscle that modifies its shape and we also added some cognitive function. We get feedback so we know exactly how the muscle bends. So we are able to sense and act upon it to control the wing’s form.

We are happy because everything seems to function correctly and even better than expected. This is a world first, so we are more than satisfied ; quite moved, in fact...

ITV Christophe Cos

The advances we are aiming for are many-fold. They depend on which phase of the flight we are looking at. One possible benefit for instance is noise reduction during takeoff and landing. This is directly linked to the airplane’s aerodynamics.

At cruising speeds, we hope to reduce the drag. This is the force that counters the plane’s forward motion. By reducing this drag, we are going to boost the aircraft’s efficiency and cut its fuel consumption.

What will be the next step ? How do we go from a lab experiment to the wing of the future ?

We are now going to try to capitalize on our results – try and go from the small-scaled model that we have in the lab to a full scale that will enable us, I hope, to equip a one-to-two meter span wing.

In approximately a year, we are going to test an intermediate model in this wind tunnel. If the concept keeps its promises, the next step will be to lauch a pre-development industrial phase with Airbus and its wing experts. We eventually hope to be able to conduct an actual in-flight test.

The wings of the future

11.13.2015

To build the airplanes of tomorrow, researchers are turning to Nature for inspiration. But how can we copy a bird's muscles, feathers and brains? With electroactive morphing, piezoelectric turbulence control and real-time feedback loops.

About this video

Original title:

Wings of the future

Production year:

2015

Length:

7 min 10

Director:

Claude Delhaye

Producer:

CNRS Images

Speaker(s) :

Marianna Braza

CNRS senior researcher

Institut de Mécanique des Fluides de Toulouse

CNRS / Université Toulouse Paul Sabatier/ Coordinator of the Morphing projects at the SMARTWING platform.

Jean-François Rouchon,

University Professor, Institut National Polytechnique de Toulouse

Director of the ENSEEIHT, École nationale supérieure d'électrotechnique, d'électronique, d'informatique, d'hydraulique et des télécommunications

Laboratoire Plasma et Conversion d’Energie (LAPLACE)

CNRS / Université Toulouse Paul Sabatier /

Karl-Joseph Rizzo

Postdoctoral fellow in electrodynamics and aerodynamics.

Christophe Cros

Airbus engineer, Emerging Technologies and Concepts - Toulouse

CNRS senior researcher

Institut de Mécanique des Fluides de Toulouse

CNRS / Université Toulouse Paul Sabatier/ Coordinator of the Morphing projects at the SMARTWING platform.

Jean-François Rouchon,

University Professor, Institut National Polytechnique de Toulouse

Director of the ENSEEIHT, École nationale supérieure d'électrotechnique, d'électronique, d'informatique, d'hydraulique et des télécommunications

Laboratoire Plasma et Conversion d’Energie (LAPLACE)

CNRS / Université Toulouse Paul Sabatier /

Karl-Joseph Rizzo

Postdoctoral fellow in electrodynamics and aerodynamics.

Christophe Cros

Airbus engineer, Emerging Technologies and Concepts - Toulouse

Recent videos

Video